/ The Brewery / Production Process

Production Process

Milling

The first step of the production process begins with the milling of the malt. This one is obtained by the malting process of soaking, germination, and kilning of grain, barley most often. Milled with the help of a hammer mill, the malt is reduced to a fine flour which will allow a maximum alteration of the starch (energy reserve of the grain) into among others fermentable sugar. The fine milling allows optimal work of the enzymes during mashing.

Mashing

Two fundamental operations take place in the mash tun: mashing consists of mixing the flour with water preheated to 63°C, drawn from a groundwater source located 70 m below the brewery, and forming a mixture called "mash". The brewing method applied is the infusion: the temperature steps, carefully defined by our master brewers, are applied so that the resources of the malt are transformed into substances assimilable by the yeast.

Wort filtration

The mash is then filtered to separate the liquid and the solid parts. The liquid part - the wort - will be pumped to the boiling vessel. The solid residue - the spent grains – is collected by local farmers and used as a cattle feed supplement. It is said that the Rhodian cows love it!

Boiling

The wort is then brought to boil at 100°C. Boiling sterilizes the wort. This is also when the hops are added: a first part is added at the beginning of the boiling process in order to extract the bitter compounds; a second part is added at the end of the boiling process, in order to extract the aromas that are more sensitive to heat. Aromas that will be present when tasting the beer!

Whirling and cooling

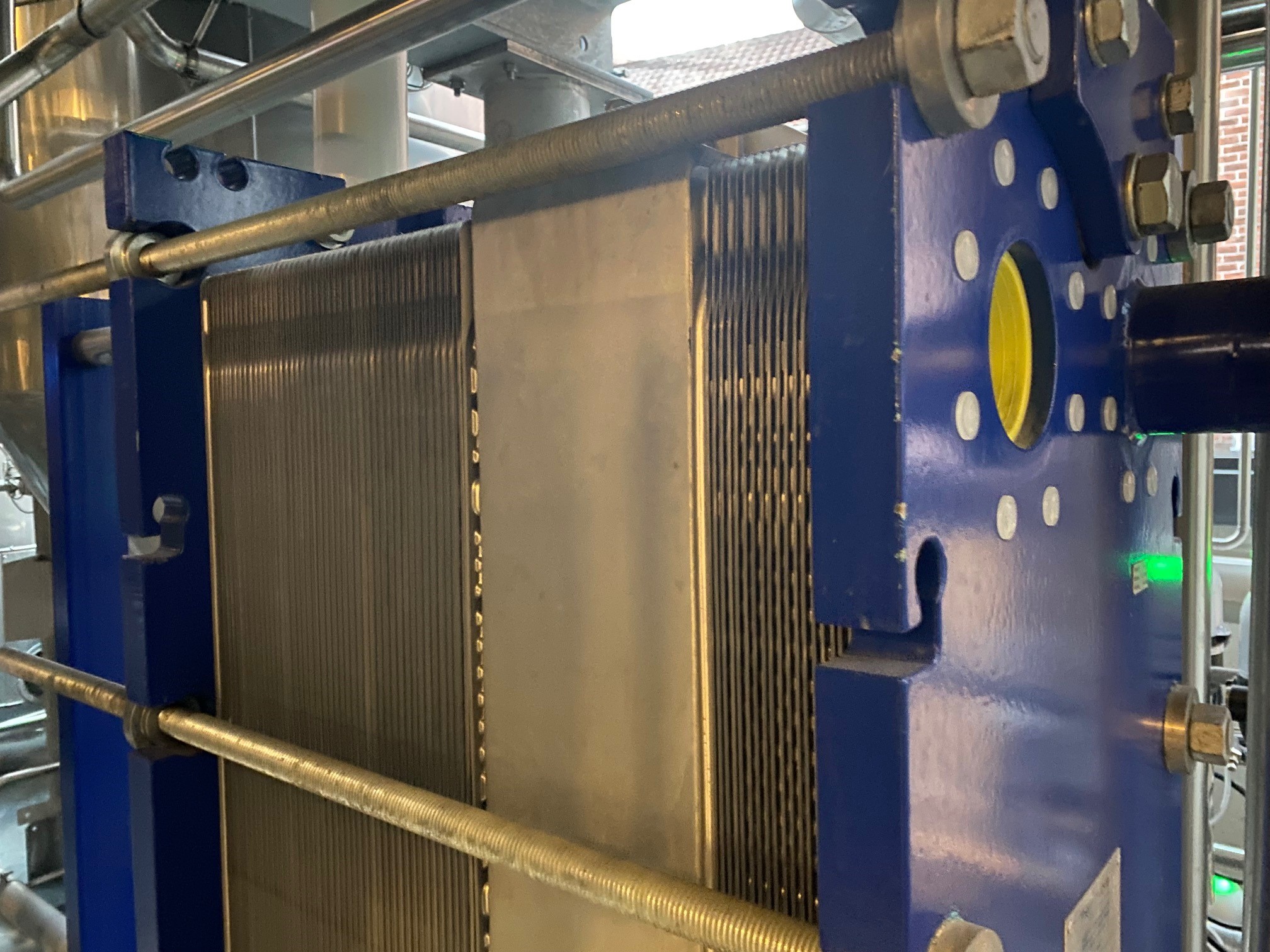

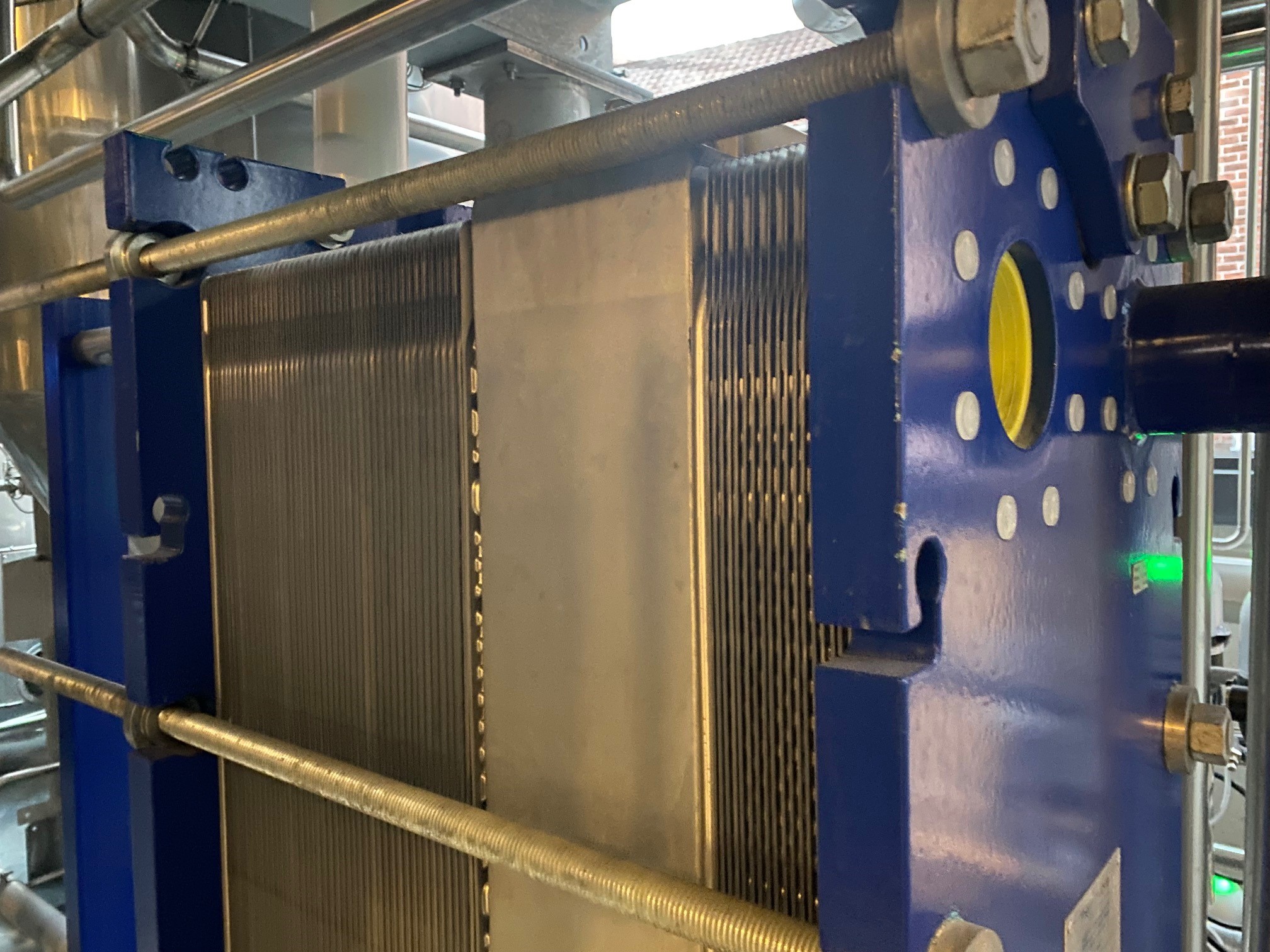

As soon as the boiling process is over, the wort is pumped to a Whirlpool to create a centripetal force which concentrate the particles (the trub) in the center on the bottom of the vessel.

The wort, free of the trub, is then pumped to a heat exchanger to be cooled down at the required fermentation temperature. As part of the reduction of the ecological footprint, the energy, in the form of heat, is recovered by preheating the water for the following brews.

Fermentation

The yeast is added to the cooled wort. The yeast used is a strain historically linked to the brewery. The yeast will transform the fermentable sugars in the wort into alcohol and carbon dioxide. It will also play a major role in the organoleptic characteristics of the beer. The fermentation takes between 4 to 5 days. It takes place between 22°C and 25°C. This is called a "top fermentation". At the end of this process, we speak of "green beer". A large part of its fruity and flowery character is already acquired.

Green beer transfer

After fermentation, the beer is cooled and centrifuged to remove the excess yeast. The yeast residues are recovered and used as a cattle feed supplement.

Maturation

This stage consists in letting the beer mature for several weeks at 0°C. During this time, the beer will subtly shape itself (bitterness refinement, foam stabilization, clarification by sedimentation). We can also, during this stage, add hop flowers to extract its aromas . This is called dry hopping and will accentuate the fresh, fruity and floral side of the beer.

Beer filtration

The beer at the end of the maturation process is clarified by a centrifuge called a polisher. The goal is to make the beer more or less clear according to the recipe.

The last yeast cells will be eliminated during this step.

Bright beer storage

The beer is stored before packaging in bright beer tanks in order to give the laboratory time to validate its quality by analysis and tasting.

Bottling

At the end of the maturation process, the filtered beer is finally bottled. Sugar and fresh yeast are added to trigger the refermentation process in the bottle, just like for champagne.

Bottle refermentation

After the bottling, the beer will rest in warm rooms during two weeks, for a second fermentation.

The yeast will ferment the sugar added to the bottle to produce a little more alcohol but especially the carbon dioxide that will make it sparkling. It is finally ready to be tasted!

Cheers!

Milling

The first step of the production process begins with the milling of the malt. This one is obtained by the malting process of soaking, germination, and kilning of grain, barley most often. Milled with the help of a hammer mill, the malt is reduced to a fine flour which will allow a maximum alteration of the starch (energy reserve of the grain) into among others fermentable sugar. The fine milling allows optimal work of the enzymes during mashing.

Mashing

Two fundamental operations take place in the mash tun: mashing consists of mixing the flour with water preheated to 63°C, drawn from a groundwater source located 70 m below the brewery, and forming a mixture called "mash". The brewing method applied is the infusion: the temperature steps, carefully defined by our master brewers, are applied so that the resources of the malt are transformed into substances assimilable by the yeast.

Wort filtration

The mash is then filtered to separate the liquid and the solid parts. The liquid part - the wort - will be pumped to the boiling vessel. The solid residue - the spent grains – is collected by local farmers and used as a cattle feed supplement. It is said that the Rhodian cows love it!

Boiling

The wort is then brought to boil at 100°C. Boiling sterilizes the wort. This is also when the hops are added: a first part is added at the beginning of the boiling process in order to extract the bitter compounds; a second part is added at the end of the boiling process, in order to extract the aromas that are more sensitive to heat. Aromas that will be present when tasting the beer!

Whirling and cooling

As soon as the boiling process is over, the wort is pumped to a Whirlpool to create a centripetal force which concentrate the particles (the trub) in the center on the bottom of the vessel.

The wort, free of the trub, is then pumped to a heat exchanger to be cooled down at the required fermentation temperature. As part of the reduction of the ecological footprint, the energy, in the form of heat, is recovered by preheating the water for the following brews.

Fermentation

The yeast is added to the cooled wort. The yeast used is a strain historically linked to the brewery. The yeast will transform the fermentable sugars in the wort into alcohol and carbon dioxide. It will also play a major role in the organoleptic characteristics of the beer. The fermentation takes between 4 to 5 days. It takes place between 22°C and 25°C. This is called a "top fermentation". At the end of this process, we speak of "green beer". A large part of its fruity and flowery character is already acquired.

Green beer transfer

After fermentation, the beer is cooled and centrifuged to remove the excess yeast. The yeast residues are recovered and used as a cattle feed supplement.

Maturation

This stage consists in letting the beer mature for several weeks at 0°C. During this time, the beer will subtly shape itself (bitterness refinement, foam stabilization, clarification by sedimentation). We can also, during this stage, add hop flowers to extract its aromas . This is called dry hopping and will accentuate the fresh, fruity and floral side of the beer.

Beer filtration

The beer at the end of the maturation process is clarified by a centrifuge called a polisher. The goal is to make the beer more or less clear according to the recipe.

The last yeast cells will be eliminated during this step.

Bright beer storage

The beer is stored before packaging in bright beer tanks in order to give the laboratory time to validate its quality by analysis and tasting.

Bottling

At the end of the maturation process, the filtered beer is finally bottled. Sugar and fresh yeast are added to trigger the refermentation process in the bottle, just like for champagne.

Bottle refermentation

After the bottling, the beer will rest in warm rooms during two weeks, for a second fermentation.

The yeast will ferment the sugar added to the bottle to produce a little more alcohol but especially the carbon dioxide that will make it sparkling. It is finally ready to be tasted!

Cheers!

The ingredients

Water

Water is a key ingredient in the brewing process. Not only does it constitute up to 90% of the finished product, but it also influences its organoleptic profile (how it affects our senses). Water was drawn from a groundwater source 70 meters below the old brewery. Following the relocation of the brewhouse, the water used still comes from the same water table. Its hardness is a favorable characteristic for beers of high fermentation.

Barley

Our master brewers choose the raw materials with the greatest care, including malts and hops. Most of the brewing barley comes from France and is malted in Belgium. The temperature of the air used to dry the malt will determine its color. If the air temperature is 80°, the malt will give its blond color to the beer. If the temperature is higher, the color will be more amber or brown.

The hops

Like malts, the best hops are selected for their organoleptic properties. In brewing, only the female flowers of the plant are used. They secrete bitter resins and essential oils which bring bitterness and aroma to the beer. For dry hopping, whole hop flowers (cones) are used.

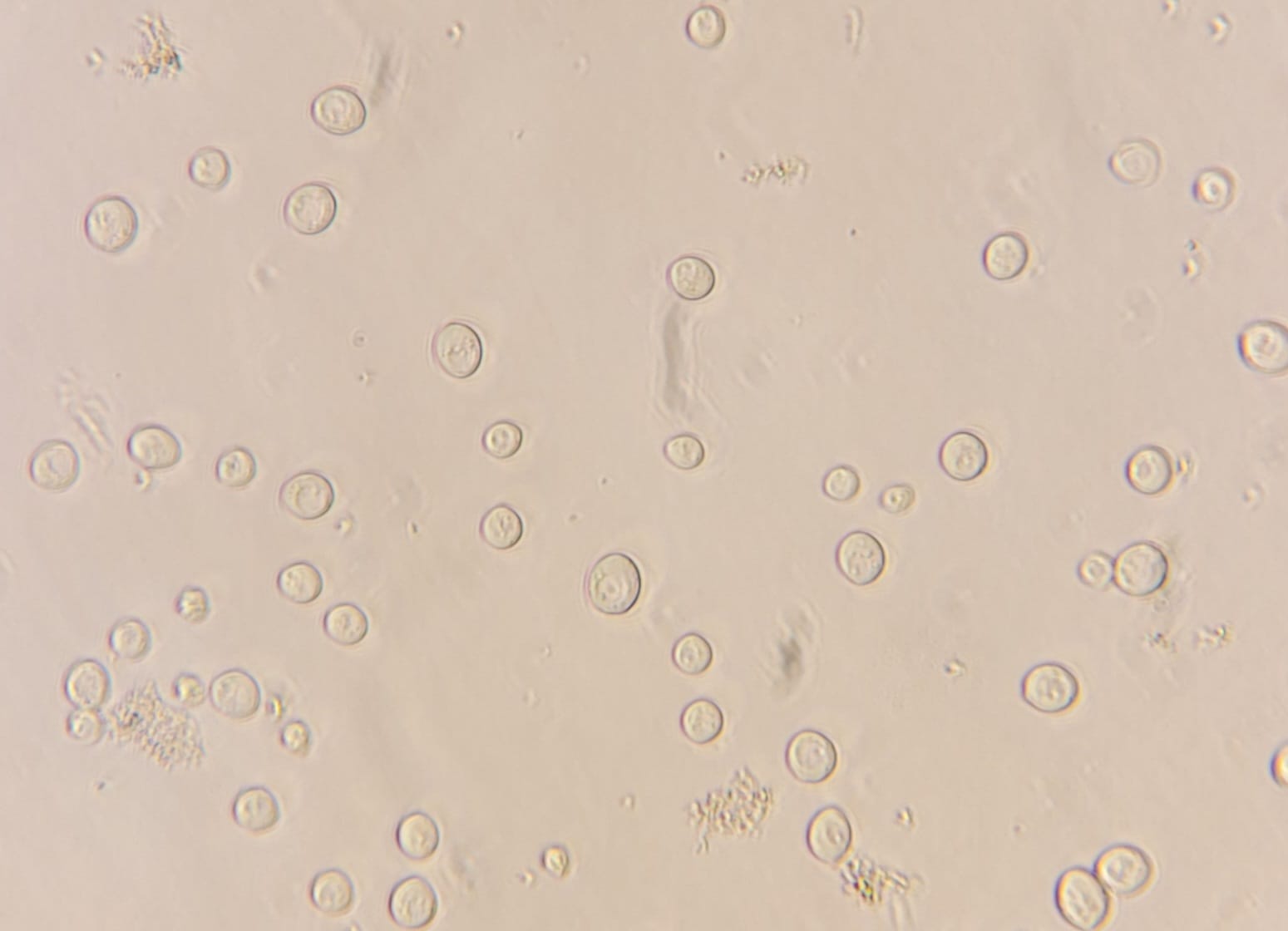

The yeast (Saccharomyces cerevisiae)

Yeast is a unicellular microscopic fungus. The

St-Feuillien Brewery has its own strain of Belgian top-fermenting yeast. It has a good tolerance to temperature, alcohol, and density. Its fermentation is quick. It’s also slightly dusty in texture, which brings a variety of flavors from its surrounding environment. It has a slight phenolic character that gives a spicy profile to our beers.

Spices

Spices are used in the production of many of our beers (especially our Abbey beers). They contribute to the complex character of our beers and are an integral part of the brew masters' secrets.

Our master brewers

They develop with passion the recipes of the St-Feuillien Brewery beers and do everything possible to offer beers of excellent and constant quality to the consumer.